10 Mar As a landscape lighting business owner I think we can sometimes learn more from our failures than our successes

By Mike Gambino

By Mike Gambino

The phone call couldn’t have come at a worse time as we are currently in the midst of a large project and have several more in line to start after its completion. This is on top of the interspersed maintenance jobs on several other established systems each and every week that we are responsible for. It was Mark Carlson of Avalon lighting on the line advising me that we had a problem at one of the projects we collaborated on last year in northern California (420 miles from our shop in southern California) and completed in two phases the fall of 2015 and the spring of 2016. More on this later but this was the second call in regards to that project the first coming a few weeks earlier. During this first call he said that the owners had reported that a number of the lights were out so he went out to investigate. He did a tracery look and guesstimated that there were a few fixtures out and asked me to ship him 6 LED module replacements which he would replace under warranty for the client. This struck me as being highly unusual to have this number of failures after only 18 months (completion of phase I) and 12 months (completion of phase II). So I shipped him the replacements immediately and waited to hear back that he had made the system whole again. California has had historic rainfall of late so much so that the 7 year long drought in Northern Cal has officially been lifted so it took a week or so for the first day without rain before Mark could get a chance to go out and make the replacements and get the system back to normal.

When he did get out to the site he was shocked to find that there were a whole lot more than 6 lights out in fact there was a much greater problem than that. Many of the fixtures had severe water intrusion, bodies either a quarter to half full of water or some moisture apparent under the glass lens. Even more shocked was I because the fixtures in question are mine. My pride and joy, Gambino landscape Lighting fixtures designed personally by myself and built exclusively for us and assembled right in our own shop by the same Gambino team members who install them. We also do all of the silicone seals of the glass lenses and wire escapes on the fixtures to ensure that there will never be water problems. In spite of this on very rare occasion we have an issue or two with slight moisture inside a fixture which is discovered and mediated at our first or second maintenance visit but never to the point of losing an LED from getting soaked in water.

You are only as strong as your weakest link

You are only as strong as your weakest link

Mark had described that the silicone seal on the lenses were tacky and had turned a bluish green in color and that he could push the glass right out of the lens holder on the most affected fixtures. This should never happen for the lifetime of the fixture and clearly the silicone sealant had failed. We use a premium brand of silicone and a tube of it costs roughly $8. We can do around 30 fixtures with one tube so there is about .25 cents worth of silicone on the fixture securing it from water intrusion. How could a product that costs us TWENTY FIVE CENTS cost us several thousands of dollars in losses.

Silicone is a chemical oil based product that is clear and thick in consistency and when exposed to air should be dry and waterproof in 30 minutes that is what it says on the tube at least. It also says that it is 100% lifetime Guaranteed (hah). If you look at the fine print it says for best results give it 24 hours to cure in a dry environment. The fixtures in question had silicone applied in our shop on a non humid day and had 2 weeks to cure before being installed in the project. On top of this whenever we have products that are going to be installed 75 miles outside of our shop we give each and every fixture double the amount of care and scrutiny in order to avoid issues like this. In addition when we came back to this project 6 months later in the spring of 2016 to complete phase II we performed a maintenance on phase I and opened up each fixture to clean the lenses and every fixture was bone dry. And these fixtures went through a particularly wet rainy winter in 2015-16. So to tell you that we made every precaution possible would be under stating it.

Decisions had to be made and made fast

Decisions had to be made and made fast

More rain is coming, the client has lamps out and are being inconvenienced, the Gambino name is on the fixtures. I as the business owner and responsible individual would have to make a decision and move fast. Initially Mark thought if I shipped replacement product to him and I took a flight up we together could dry out the fixture bodies, pop out the glass lenses, apply fresh silicone sealant (and hope it dries before the next rain), replace the bad LED’s and put this behind us. I had no way to gauge the extent of the damage without actually walking the site and seeing it with my own eyes but after consulting with my team they brought up a good point. The same silicone that was used on the glass lens tops was also used on the wire escape seals at the bottom of the fixture body so what if those seals had failed too? By fixing only the top leaks and not the bottom would be going from the pan to the flame as this would not be a permanent fix.

In addition, heavy rains were also predicted to return by the weekend and last for days so applying silicone in the field to already wet soaked fixtures in humid ambient air with storms coming was risky and ill advised.

I weighed all of the possibilities in my mind and the answer was clear. Drop everything that we were currently doing and myself and a crew of two would head up to Northern California the next day to make this right. Mark made a count of the amount of fixtures that he thought we’d need to replace. 42 fixtures and LED modules with adjustable brightness switch built in and assorted optic lenses is what we loaded into the SUV along with the tools that we needed and we headed out 5 am the following morning. We arrived at the site at noon and ate our lunch and started our work in earnest at 12:15. After a short inspection with Charlie we knew we had a job on our hands and needed to get to work right away.

Mark met us on site and we got straight to work. Mark dug up and exposed all of the fixture connections. I went through each and every fixture individually cutting the cables at the power cable connections removing the water affected ones. Charlie prepared the new fixtures with the appropriate brightness level and optic that I called out to him. the new fixtures were hand placed and adjusted by me just like every project we do. Eddie made the with new connection and sealed it with a torch and when hardened and dry, bunched and tied with a cable tie and reburied by Mark and Eddie under the fixture. In between Eddie went up in the trees and checked all of the fixtures. None of them were out or had water in them so obviously they had been sealed with a different tube of silicone.

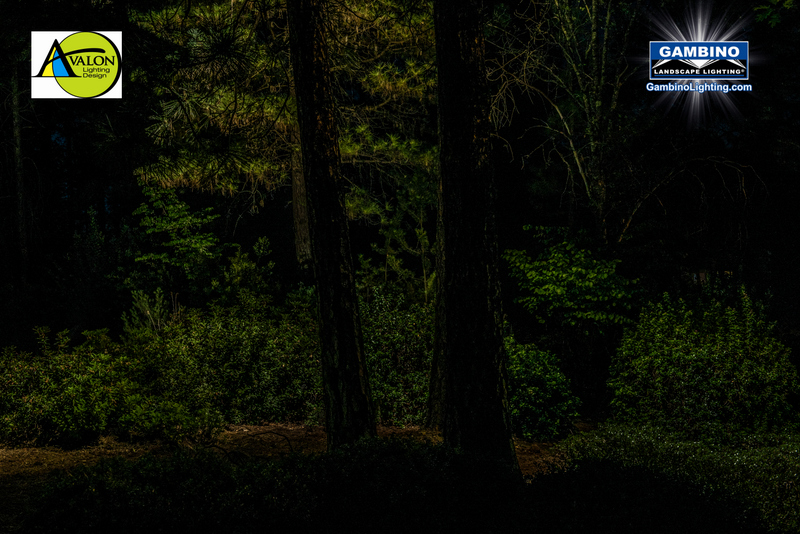

Once we had completed this task we were losing daylight fast. We still had to go back through each of our homerun connections to test voltage and amperage loads at the transformer with Mark making note on his as built plan. Literally as nightfall came Eddie and Mark were burying the last of the fixture connections, we made a few tweaks and I got my camera out to get a few updated shots. We observed our project feeling proud and left the site at 7pm with the feeling that we had solved the issue and there would not be any further problems.

We had dinner at a restaurant and reflected on how well everything came together in such a short time and how as a team we had worked together to get this done so quickly and before the next set of rain storms.

Me and my team went back to the hotel showered and went to sleep to arise the next morning and leave for our trip back to LA at 4:45 AM. We arrived back at the shop at 11AM, unloaded the truck and went though the boxes of returned products to assess the loss.

In total we had removed and replaced 32 complete fixtures, 38 LED modules (19 of which were lost from getting water soaked) and six glass lens/shrouds. It was clear the silicone had failed in a big way to the degree we have never seen before.

This is the single most catastrophic loss of product and labor, with several thousands of dollars in direct costs to the company to rectify, that Gambino landscape Lighting has ever experienced in nearly 27 years of business. And in the spirit of Murphy’s Law happened on a project that is far outside our normal service area on product that had received extra special attention to prevent such issues. This can be chalked up to only one thing and one thing only and that is sometimes even with the best planning and intentions “STUFF HAPPENS” !

So what is to be learned from this event that can make lemon aid out of lemons ?

So what is to be learned from this event that can make lemon aid out of lemons ?

Integrity and being true to your Brand and not just your marketing message. Gambino landscape Lighting Products and lighting systems are custom designed and built to last. I think that a company is defined not by how many failures it has but how they do the right thing in handling those failures quickly and efficiently. I made the right decision albeit it was not the cheapest or simplest one to make. To bring my crew with me lost two days of production to replace in whole and not just repair in place affected fixtures in the field. I could have succumbed to the temptation of hoping for the best and to “get away with” the least expensive cure. However this decision making has not been the way that I have built Gambino landscape Lighting into the premier design build contractor company in the nation. Nothing we do is the easy or cheap way because to do so would be against our culture and to subvert our values. So the decision came easy. For this I am very proud. I also know that some contractors of lesser integrity would have become the invisible man and disappeared when faced with this problem and significant expense to repair. By saying this I am not looking for a pat on the back or looking for kudos for doing the right thing but simply stating the facts.

Build a team that is as responsive as the business owner and willing to correct problems ASAP without complaint. Waking up early on two successive mornings (3 am) for no additional pay beyond their normal daily day rate to travel and be expected to spring in to action and produce efficiently and effectively performing under pressure without complaint after a long road trip is truly a blessing.

Developing a valuable collaborative partner on select projects. To have a collaborative partner like Mark Carlson who has our back and is my eyes and ears on this remote project who accurately described the situation with the need to handle it right away so I could make the right decision on how much product and labor force to bring to get it done is also a blessing. He also took the day away from his normal schedule and worked with us.

Sufficient back up stock available immediately in our own shop and not someone else’s shelf. As a design build contractor having a sufficient amount of product in our shop ready to go at any given time right in our own shop is priceless for our clients. I know for a fact that no other company on the planet could have responded to and fixed this problem as fast as we did with minimal amount of inconvenience to the client.

Had this been any other product line of similar quality and equivalent cost the process would have gone down like this. The contractor would have visited the site and discovered the problem and contacted the distributor where the purchase was made. A local manufacturer’s sales rep would have been sent out to view the situation. He/she would have to report back to the manufacturer. Manufacturer would have to decide what they would do. If decision was made to replace it would take several weeks to get product to the contractor who in turn would go out to handle the situation. More than likely at this magnitude there would have been more spot replacements made instead of the complete replacements that we made without question.

Having multiple service vehicles available to efficiently roll out at a moments notice. The fact that we were able to use a smaller company SUV vehicle and not our normal large work box truck saved about 2 hours of travel time each way since we didn’t need to stop at the number of truck scale/ weight inspection stations along the way from southern to Northern California therefore making our travel cost the most efficient as possible in regards to time and cost per mile of travel. Gambino landscape lighting has fully stocked backup trucks equipped the same way that sit idle and used only when primary service vehicles break down or need to go in for service. This is an extra cost to the company however is a priceless benefit for our client who needs it done NOW without excuse.

Having a small and nimble business that is capable of turning on a dime. Eliminate the bureaucracy from the decision making process. Decision by deliberation, vote and committee takes time and aggravates an already vexing problem. Being able to definitively and effectively make decisions and execute quickly and effectively is a valuable business virtue. A patient can be lost when a doctor hesitates to act on the operating table. The same can be said when a business owner hesitates to correct a critical problem for a client.

This landscape lighting blog is published by Mike Gambino of Gambino landscape lighting inc. all

This landscape lighting blog is published by Mike Gambino of Gambino landscape lighting inc. all  rights reserved. Mike is a professional landscape lighting system designer/ builder and has been designing, installing and maintaining landscape lighting systems for more than 27 years. Mike resides in the Los Angeles area with his wife and 2 sons. To visit his website go to www.Gambinolighting.com . To inquire about hiring Mike please click here .

rights reserved. Mike is a professional landscape lighting system designer/ builder and has been designing, installing and maintaining landscape lighting systems for more than 27 years. Mike resides in the Los Angeles area with his wife and 2 sons. To visit his website go to www.Gambinolighting.com . To inquire about hiring Mike please click here .

Blog articles may be published with permission on other websites without editing or removing links.

Mark Carlson

Posted at 17:21h, 10 MarchMike….wow! And yes, another great experience working with you and your team. You are absolutely, 100% right about how your integrity…..our integrity, as a collaborative team is one that you can’t put a price on. Most will fail to recognize this commitment until it happens to them. I’m really proud to work with you because there is no other in today’s market that has the same discipline and belief in what it is you do.

Thank you for the stellar work ethic and outstanding products….I have found no other to meet these same standards.

Mike Gambino

Posted at 08:40h, 12 MarchMark thank you for your kind words. I am blessed to have a collaborative business partner in you that I can honestly say the same of. There are way too many in this business who are in it for the quick buck. Slam low quality product in the ground with poor installation techniques and when it all falls apart are nowhere to be found.